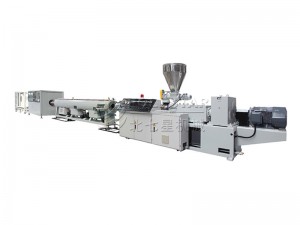

Sj Series Single dabaru Extruder

Awọn abuda

Ẹrọ extruder ṣiṣu nikan dabaru le ṣe ilana gbogbo iru awọn ọja ṣiṣu pẹlu awọn ẹrọ iranlọwọ ti o kan, gẹgẹbi fiimu, paipu, ọpá, awo, o tẹle ara, tẹẹrẹ, Layer insulating ti okun, awọn ọja ṣofo ati bẹbẹ lọ. Nikan dabaru extruder ti wa ni tun lo ninu graining. Nikan dabaru ṣiṣu extruder oniru ti ni ilọsiwaju, gbóògì agbara jẹ ga, plasticization jẹ ti o dara, ati agbara ni kekere. Yi ṣiṣu extruder ẹrọ adopts lile jia dada fun gbigbe. Awọn extruders ṣiṣu wa ni ọpọlọpọ awọn anfani.

A tun ṣelọpọ ọpọlọpọ awọn iru ṣiṣu extruders bii ẹrọ ṣiṣu extruder sj25 mini extruder, kekere extruder, lab ṣiṣu extruder, ṣiṣu pellet extruder, twin screw extruder, PE extruder, pipe extruder, dì extruder, pp extruder, Polypropylene Extruder, pvc extruder ati bẹ bẹ. lori.

Awọn anfani

1. Gigun gigun laarin ọfun ifunni ati dabaru lati mu ilọsiwaju pọ si

2. Eto iṣakoso iwọn otutu deede lori apakan kikọ sii lati baamu awọn pilasitik oriṣiriṣi

3. Oto dabaru oniru lati se aseyori ti o ga plasticizing ati awọn ọja didara

4. Gearbox ti iwọntunwọnsi torsion giga lati mọ iṣiṣẹ iduroṣinṣin

5. H fireemu apẹrẹ lati dinku gbigbọn

6. PLC iṣẹ nronu lati rii daju imuṣiṣẹpọ

7. Itọju agbara, rọrun fun itọju

Imọ Data

|

Awoṣe | L/D | Agbara(kg/h) | Iyara iyipo (rpm) | Agbara mọto (KW) | Giga aarin (mm) |

| SJ25 | 25/1 | 5 | 20-120 | 2.2 | 1000 |

| SJ30 | 25/1 | 10 | 20-180 | 5.5 | 1000 |

| SJ45 | 25-33/1 | 80-100 | 20-150 | 7.5-22 | 1000 |

| SJ65 | 25-33/1 | 150-180 | 20-150 | 55 | 1000 |

| SJ75 | 25-33/1 | 300-350 | 20-150 | 110 | 1100 |

| SJ90 | 25-33/1 | 480-550 | 20-120 | 185 | 1000-1100 |

| SJ120 | 25-33/1 | 700-880 | 20-90 | 280 | 1000-1250 |

| SJ150 | 25-33/1 | 1000-1300 | 20-75 | 355 | 1000-1300 |

Nikan dabaru Extruder

Da lori 33: 1 L / D ratio fun apẹrẹ dabaru, a ti ni idagbasoke 38: 1 L / D ratio. Ti a ṣe afiwe pẹlu ipin 33: 1, ipin 38: 1 ni anfani ti 100% ṣiṣu, mu agbara iṣelọpọ pọ si nipasẹ 30%, dinku agbara agbara to 30% ati de ọdọ iṣẹ extrusion laini fẹrẹẹ.

Simens Fọwọkan iboju ati PLC

Waye eto ti o dagbasoke nipasẹ ile-iṣẹ wa, ni Gẹẹsi tabi awọn ede miiran lati jẹ titẹ sii sinu eto naa.

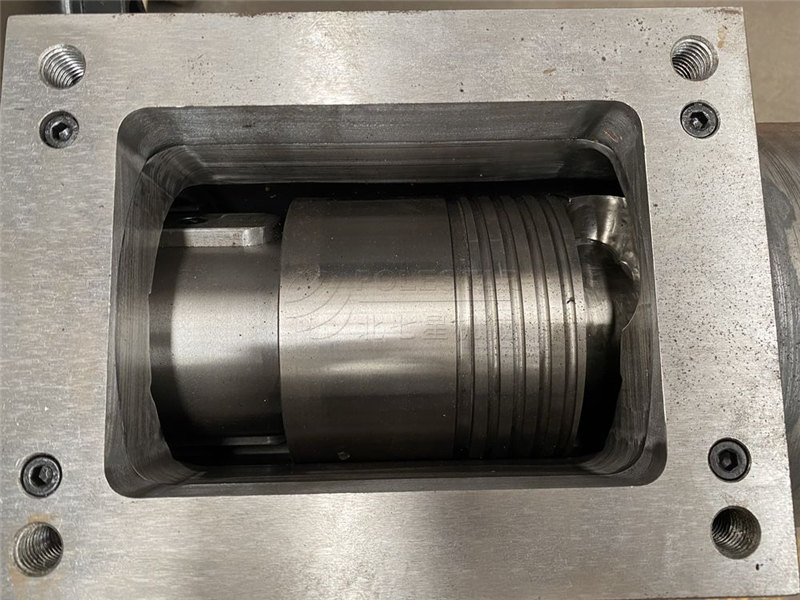

Special Design of dabaru

A ṣe apẹrẹ dabaru pẹlu eto pataki, lati rii daju pilasitik ti o dara ati dapọ. Unmelted ohun elo ko le ṣe yi apa ti dabaru, ti o dara ṣiṣu extrusion dabaru.

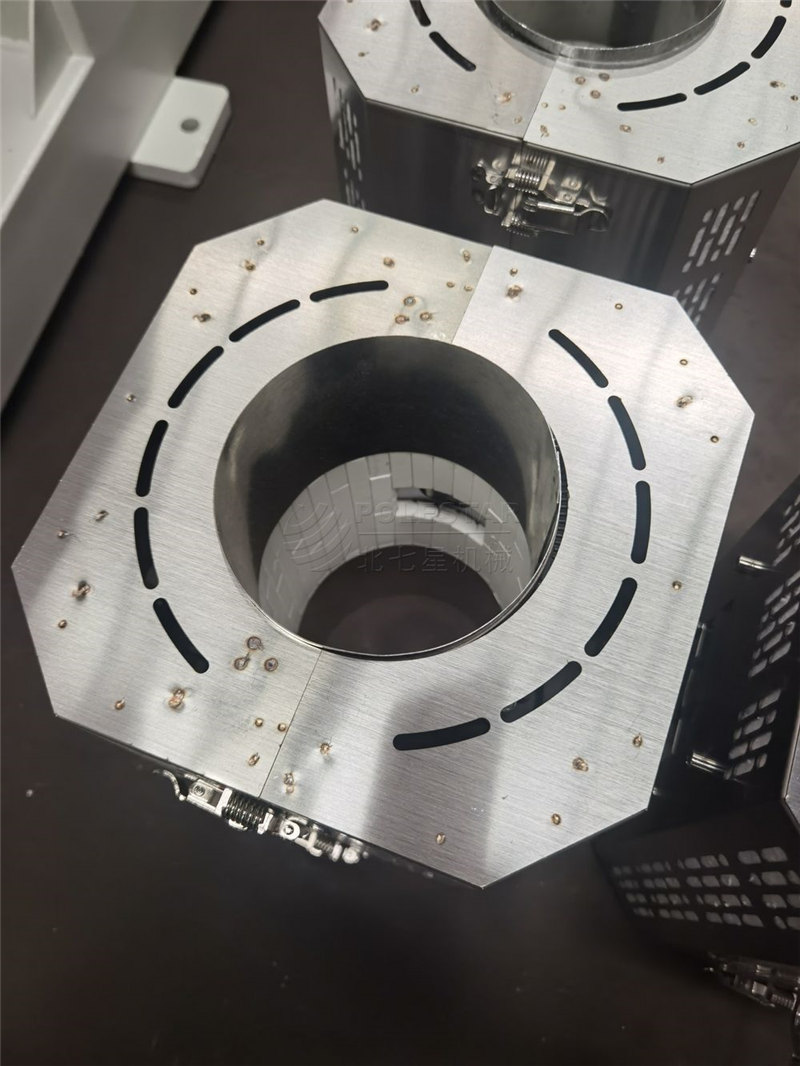

Ajija Be ti Barrel

Ifunni apakan ti agba lo ọna ajija, lati rii daju ifunni ohun elo ni iduroṣinṣin ati tun mu agbara ifunni pọ si.

Afẹfẹ tutu seramiki ti ngbona

Olugbona seramiki ṣe idaniloju igbesi aye iṣẹ pipẹ. Apẹrẹ yii ni lati mu agbegbe pọ si eyiti ẹrọ ti ngbona pẹlu afẹfẹ. Lati ni ipa itutu afẹfẹ to dara julọ.

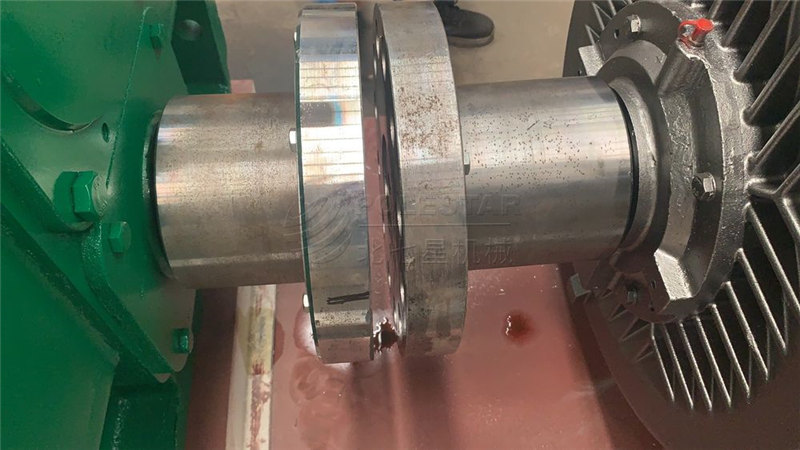

Didara Gearbox

Iṣe deede jia lati ni idaniloju ite 5-6 ati ariwo kekere ni isalẹ 75dB. Ilana iwapọ ṣugbọn pẹlu iyipo giga.

Awọn ẹka ọja

Ṣe o fẹ lati ṣafikun Ọrun si Apẹrẹ rẹ?

Kan si wa loni fun ijumọsọrọ oniru.